stray dog

Junior Member

Assume you have change your cam order from 21G to TW21?

Also, a bit caveman but before I started doing cam upgrades for friends and family, I used the blind hole puller available from AutoZone ....

The outer bearings, if heated in an oven and cams in the freezer over night, will usuall drop right on the cams......just be sure you have the dots lined up when you drop them in.

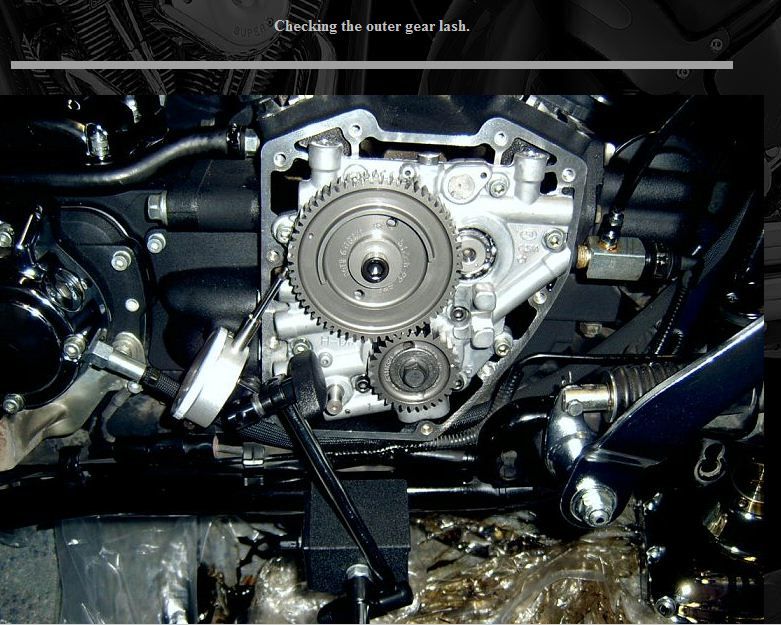

Dolt, I'm going gears (21G)...only bought the tensioner kit for oil pump & plate.

I was hoping to save $ by getting a newer pump and bolting it to my stock plate, but thats not an option as you stated in earlier post.

I already bought a tool kit for inner bearing R&R but was waiting to measure parts up for pressing plate bearings & cams. I probably will go your way "caveman" here. And watch the dots

BigAl66, I thought I had read them all! How did I miss yours? NICE lots of pics.

I didn't get a chance to go thru it all since I should be working, but plan to.

Last edited by a moderator: